We help you through the whole process and use the very best equipment to give you the most cost effective manufacturing options for your sheet metal fabrication needs.

“Whether you’re in need of prototype sheet metal parts or high-volume sheet metal fabrication, TAIWA is your trusted partner”

At TAIWA, we understand that precision is paramount. As a trusted sheet metal fabricator, we bring your concepts to life with unparalleled precision to meet your project requirements.

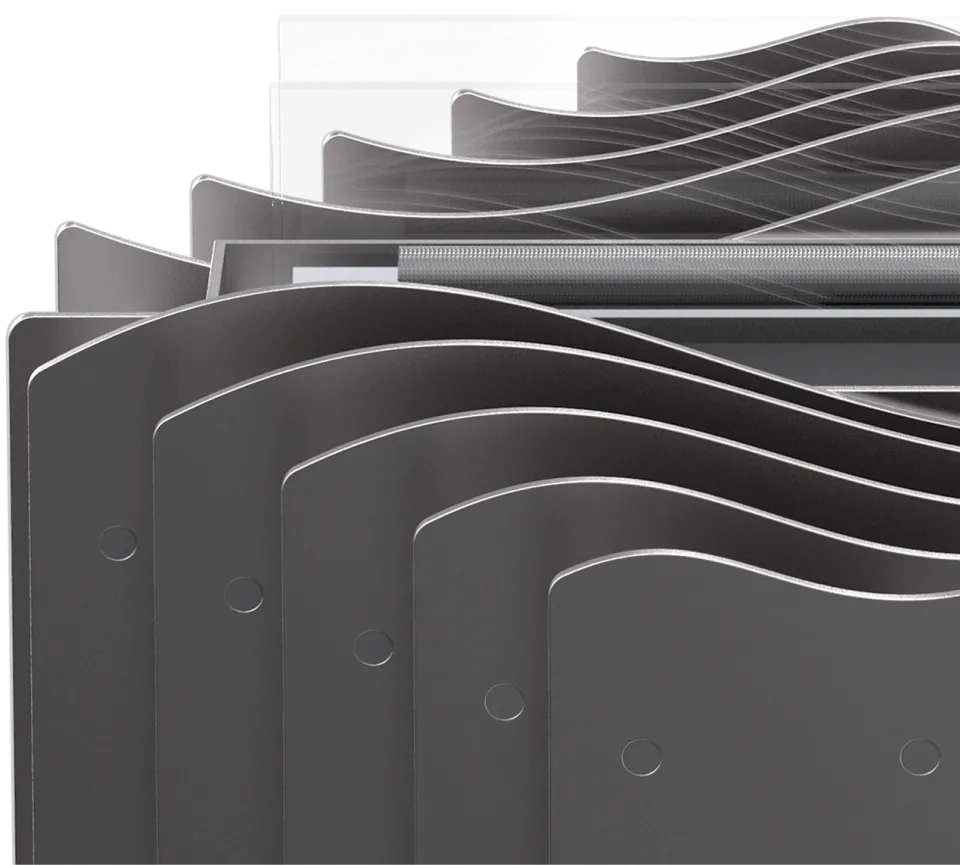

Our state-of-the-art facility is equipped with the latest in Japanese CNC sheet metal processing technology, offering everything from laser cutting and punching to metal bending and forming.

Our rapid sheet metal prototyping is a testament to our agility and commitment to meeting tight deadlines without compromising quality. For large-scale projects, our heavy gauge sheet metal fabrication capabilities ensure that every project, regardless of size, receives the meticulous attention it deserves.

Whether you’re in need of prototype sheet metal parts or high-volume metal fabrication, TAIWA is your trusted sheet metal fabrication provider. Our services encompass:

Custom Sheet Metal Parts Fabrication: Tailored solutions that fit your specific needs.

Laser Cutting Service: Cutting-edge Japanese technology for clean, precise output every time.

Precision Sheet Metal Forming: Transforming raw materials into intricate components with exacting standards.

Metal Welding Services: Skilled welding technicians for durable joints with perfect finishes.

Sheet Metal Assembly Services: Meticulous attention to detail from the initial cut to final assembly.

We use only the most up to date and advanced Japanese Laser cutting, punching and bending equipment to ensure every part is perfectly produced.

We emphasize the importance of finishing each Sheet metal component and join prior to assembly to guarantee the stable quality of large production runs.

We work with many customers from the design concept phase side by side to ensure the best sheet metal solutions to meet both your budget requirements and your expectations.

Our main fields are sheet metal parts manufacturing for industrial machinery, the optoelectronics industry, electrical control boxes, and metal closures for machinery

We have collected a range of the frequently asked questions from our customers and listed up some of questions and answers. We hope they assist you when starting new sheet metal fabrication.

If you can not find the answer you are looking for, please feel free to contact us by phone, email or contact form. We would be happy to help you in more detail.

Typically, standard quotations are provided within 5 days, while more complex design drawings may require 7-10 days for a comprehensive response.

We accept and work with design files in AutoCAD and SolidWorks formats. For 2D drawings, DWG and DXF formats are preferred, while for 3D drawings, we recommend STP and IGS formats.

We accept sketches, 2D, and 3D files. However, if providing a sketch, there may be an additional charge for computer-aided drawing services.

The lead time for sample production depends on the complexity of the drawing, the completeness of the provided files, and whether surface treatment is required. Typically, it is within 2 weeks. Feel free to contact us for a quotation.

Our company ensures confidentiality through the signing of a Non-Disclosure Agreement (NDA) between both parties. Quotations and communication are conducted through secure email channels. We employ a rigorous electronic drawing system to control and safeguard customer confidential information.

We have a team of 9 mechanical engineers in the design department and 2 product designers.

Find out our latest exhibition and news.

Choosing TAIWA means opting for a sheet metal fabricator that stands by its word to deliver excellence. Our metal fabrication and sheet metal enclosure manufacturing are the core of our extensive service offerings. Connect with us today and experience TAIWA’s expert sheet metal fabricator services.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |