Precision sheet metal parts manufacturing includes steel and non-ferrous metal processes. At Taiwa we offer a full range of sheet metal parts manufacturing and fabrication services for all types of ferrous and non-ferrous metals as well as design, assembly and marketing. Whether you need the durability and strength of steel for machinery fencing or equipment enclosures or the precision and malleability of bespoke non-ferrous metal tools or artisanal sheet metal products, Taiwa provides a full service model to meet your precision sheet metal fabrication needs.

Precision Sheet Metal Fabrication

Sheet metal fabricators in the Taiwan metal processing industries use steel and non-ferrous metals to create a wide range of products. Precision sheet metal fabrication companies need to have a good understanding of how different metals require different treatments to ensure they are correctly matched to their eventual uses. Our expert sheet metal fabricators can identify which sheet metal fabrication processes would be most appropriate for the realisation of any precision sheet metal fabrication project.

- Stainless steel fabrication

- Non ferrous sheet metal fabrication

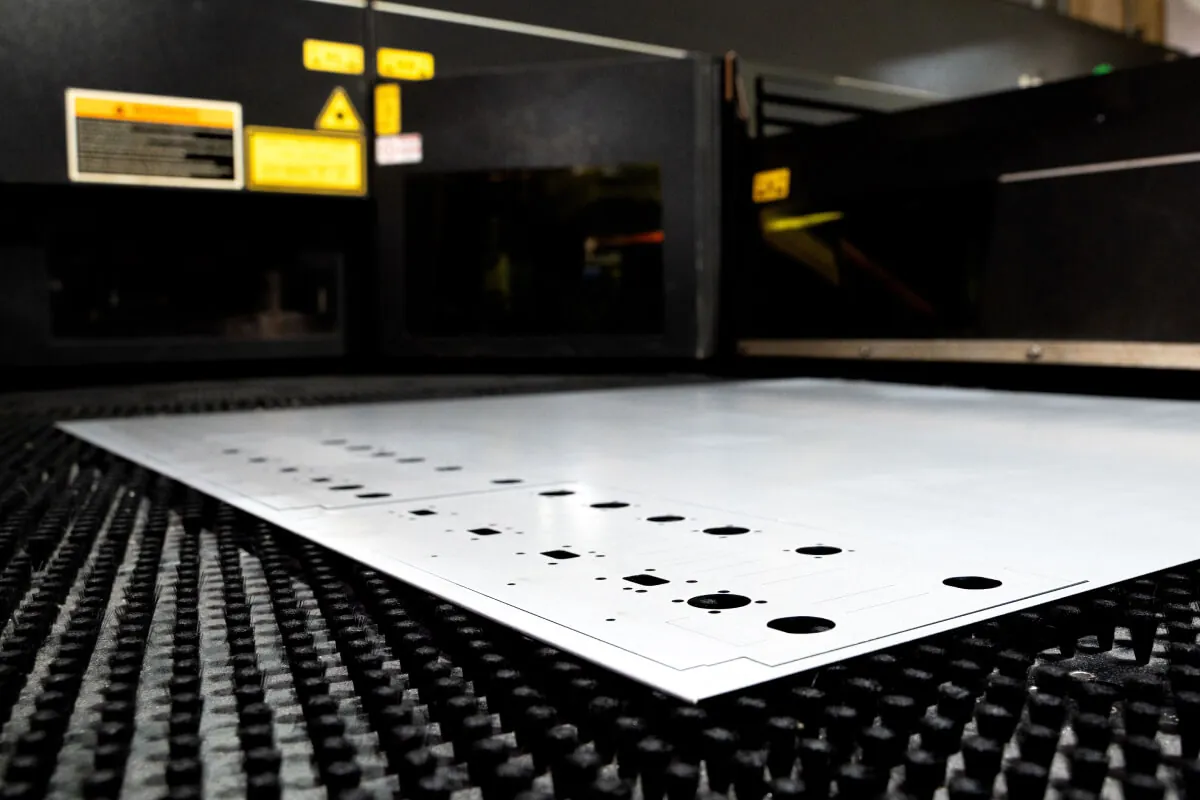

- Metal laser cutting service

- Combination laser punch cutting

- Sheet metal bending

- Sheet metal welding

- Assembly of sheet metal fabrication products

Our experience as a metal fabrication company comes from building industrial fencing, equipment and electronic enclosures, metal containers, structural steel transport shelters, and domestic tools and machinery. Our well equipped fabrication shop is expert in stainless steel fabrication and working in other ferrous metals. We also have the capabilities and skills to meet your non ferrous metal fabrication needs with our precision equipment.

What steel sheet & plate categories are used in sheet metal fabrication?

Steel is good for strength and durability, and suitable for stand-alone structures including kiosks and shelters. We provide metal bending, laser cutting services, welding, consultation and design support for precision sheet metal fabrication in steel from our convenient offices in Taiwan.

- SS400 (JIS G 3101) structural steel is a hot-rolled steel that can rust easily so is protected with treatments depending on the end use. Taiwa can provide advice to help pick the right surface treatment for any specific SS400 based metal fabrication project.

- SPHC-P (JIS G 3131) is a hot rolled steel sheet with an oxide film that needs to be removed from the surface, and is also known as ‘pickled steel sheet.’ SPHC-P is a commercial grade steel that is good for structural sheet metal fabrication projects. Commonly used in the automotive industry and for electrical equipment housings.

- SPCC (JIS G 3141) is a cold rolled hot steel sheet, which is processed for strength and uniformity. The cold rolling process improves the surface of the steel to achieve a smooth, or polished finish, and it is also known as ‘polished steel.’ This steel is typically also a low carbon steel, which makes it easier to draw and achieve an excellent finish in thin sheets that are ideal for home appliances and electrical boxes.

- SECC is SPCC cold rolled steel which has been electro-galvanized with zinc to reach an average thickness of electrolytic zinc plating of between 2 and 25 µm. Used for machine covers, machine parts, lighting equipment, building materials and transportation components.

- SGCC is hot-dip galvanized cold rolled steel sheet. This achieves a significantly thicker plating of zinc than the electrolytic process used for SECC, and results in an average plating thickness of 50-100 µm. High rust prevention makes SGCC useful for external machinery like air conditioners, ventilation equipment, and vending machines.

We are experts in stainless steel fabrication

The excellent mechanical properties and versatility of different grades of stainless steel enable stainless steel fabricators to choose specific stainless steels for improved fire resistance, low temperature ductility, hard wearing surfaces, and different degrees of corrosion resistance depending on the expected use.

- SAE 304 & 304L stainless steel (1.4301 & 1.4307) are extremely versatile, also sometimes referred to by the historic name of ‘18/8’ stainless steel due to the nominal composition being 18% chromium and 8% nickel. Commonly used in domestic and commercial kitchen and construction applications where some degree of corrosion resistance is desired.

- SAE 316 & 316L stainless steel (1.4401 and 1.4404) are stronger than 304 & 304L with higher corrosion resistance due to the addition of molybdenum to the alloy. Commonly used in saltwater marine applications and where chemical or corrosive material contact is likely.

Sheet metal fabrication using non-ferrous metals

The finesse required to work with non-ferrous metals means a metal fabrication firm has to be confident its manufacturing partner has the advanced tools required to do the job.

Our advanced tools mean we can guarantee a quality product to our clients whether you are making components for electrical, precision vehicle parts or knives and forks.

- Aluminum & aluminum alloys come in a range of grades that have excellent corrosion resistance and are very light in weight compared to steel. This makes aluminum a popular choice for sheet metal aerospace components. High heat conductivity also leads to aluminum being popular for kitchen & cooking utensils.

- Copper is highly conductive, can be polished to a bright finish, is highly malleable and easily worked into complex shapes. This makes it ideal for decorative and artisanal sheet metal fabrication, and it can be used for decoration on more functional products to improve visual aesthetics.

Choose Taiwa for precision sheet metal parts manufacturing

We offer the full range of design, manufacturing, assembly and shipping services to find the best solution for any sheet metal fabrication project, and all completed to international quality standards. Our design team use advanced AMADA CAD/CAM design software to accurately model every bend digitally in advance, including deformation and spring-back characteristics, significantly reducing prototyping time and cost overheads.

- Highly trained & expert designers & machine operators

- Expert customer service & engineering support teams

- 300 hours of employee training & examination to become a Taiwa machine operator

- Taiwan TTQS Workforce Quality Certification

- ISO 9001 & ISO 14001 certified

- Extensive library of bending dies & tooling

- Frequently calibrated Japanese AMADA cutting, punching & forming machines

- Experts in material technology

- Complex assembly capabilities with multiple processes and components

- Experts in design for manufacturability

With 20 years of experience in precision sheet metal fabrication, Taiwa uses state of the art Japanese AMADA press brakes and AMADA laser cutting and punching combination machines to guarantee extreme precision no matter how complex the design.

- Capacities up to 3000 mm sheet length

- 0.3 mm to 20 mm sheet thickness

- Flatness maintained to 0.2 mm

- Verticality within 0.15 mm

Our extensive library of tooling and forming jigs reduces setup and tooling costs for metal folding and bending, and our efficient modern manufacturing processes are greener due to reduced energy consumption and waste. Contact us to find out how our sheet metal fabrication services can easily help you create perfection in precision sheet metal parts manufacturing.