Sheet metal fabrication of complex designs makes significant demands on designers and manufacturers to ensure they get everything right from the start. Errors in design and fabrication cause prototyping and manufacturing delays and increase development costs. Let’s take a look at how Taiwa integrates design, manufacturing, and assembly to build a complex coffee roaster that has instant appeal for catering, business, or home use.

The coffee roaster: a case study in complex sheet metal fabrication

We have decades of experience in manufacturing complex sheet metal fabrication projects for our Taiwanese and global clients. This gives us many case studies that display our skills and capabilities in sheet metal fabrication and product assembly.

- Expertise in material technology

- Many different design elements

- Complex assembly requirements

We’re talking about our coffee roasting machine project for several reasons. One is that we love coffee, of course, but also because it is a challenging project that requires expertise in material technology, design, and assembly to make it successful. Coffee roasting is a technical process that requires precise temperature and airflow control, so the coffee roasting machine has to not only look good, but be extremely functional as well!

Why is a coffee roasting machine a challenging sheet metal fabrication project?

There are so many things that could go wrong with manufacturing a coffee roasting machine that it becomes a perfect case study for how to get everything right in designing and manufacturing for sheet metal fabrication.

- Hard wearing, attractive, finishes

- Heat resistance

- Corrosion and moisture resistance

- Electrical safety

- Components made of different materials

- Food grade construction

- Sensitive digital electronics

- Complex assembly requirements

As a ‘display item’ a coffee roaster needs to look good on the counter, especially if used in a commercial kitchen or coffee shop, and of course it needs to operate at a high enough temperature to roast coffee beans. All the components need to be sufficiently heat resistant, or insulated.

In the design phase the potential for differential heat expansion to change the accuracy of assembly, or cause jamming of moving parts, needs to be carefully factored into the CAD work during project design and prototyping. When you have solved all these problems, the design also needs to work to roast beans with precision to make good coffee!

What are the design features of the Taiwa coffee roasting machine?

- The interior is made of food grade stainless steel SUS304

- Roasted bean capacity 300g~500g

- 110V power appliance suitable for general & domestic use

- Two detachable silver collection baskets

- Collection baskets are easy to remove and clean to improve roasting efficiency

- Bean window and bean detector enable easy monitoring of coffee bean roasting progress

- Detachable bean funnel is easy to remove and clean regularly

- USB external connection to roasting curve software

- Temperature can be programmed to optimize the exact roast for specific beans

- Clear digital displays on control panel

- Contoured, aesthetic synthetic and wood effect control levers

How do you add accessories to sheet metal products?

The image above shows different height elevated shelves in various designs that can be included as an optional extra to suit the styling required by the customer. Another benefit of working with a multi-skilled partner on an integrated complex sheet metal fabrication project is the ability to make matching accessories and modifications in style without having to start again from the beginning with your design.

Coffee products include bean roasters, coffee machines, counter and table accessories, stands, trays, funnels and containers. This gives a large number of opportunities to add value to a commercial coffee sheet metal fabrication project because of the possibility to manufacture so many different accessories.

Working in partnership with a sheet metal fabricator who can design and manufacture accessories that complement the original design is a great way of rapidly increasing your product range while ensuring all items match and share the same look and feel as the original.

Taiwa: the perfect partner for your sheet metal fabrication project

At Taiwa, we specialize in integrated and holistic manufacturing of complex sheet metal products with a range of matching accessories that complement each other and increase the attractiveness of the product to your customers.

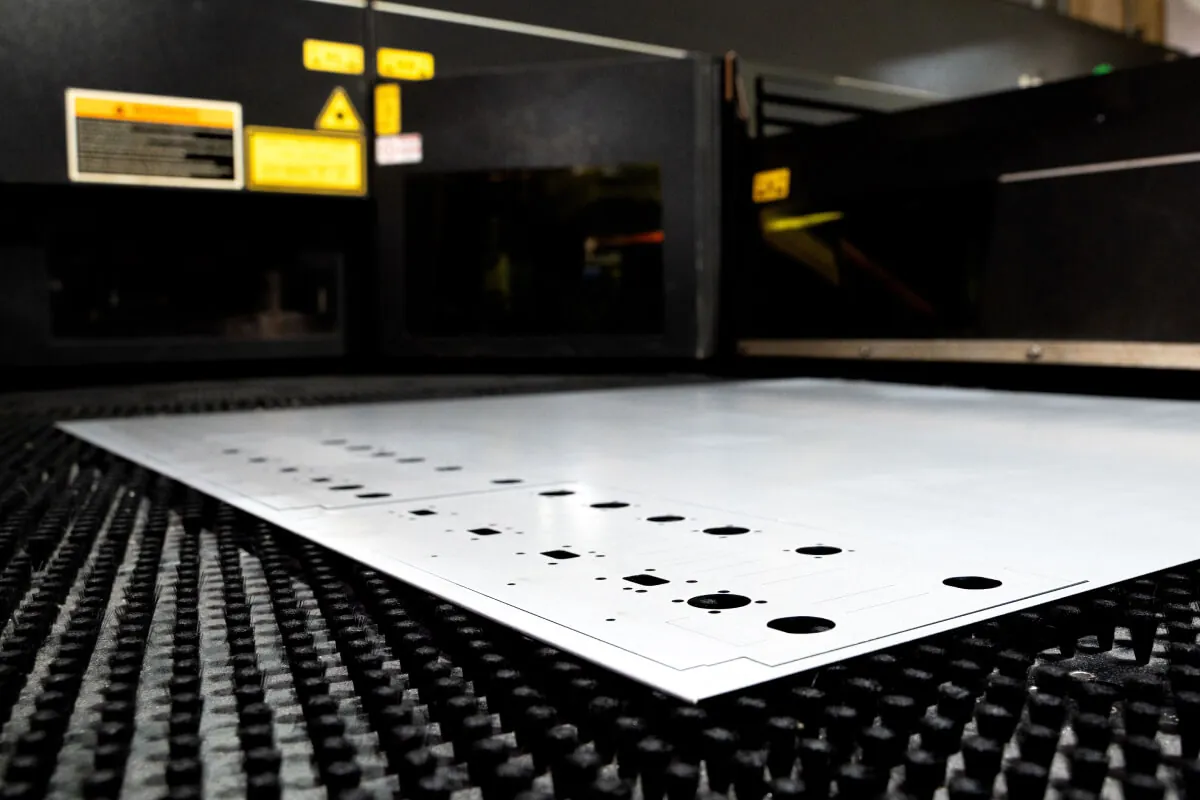

Our sheet metal fabrication skills in cutting, forming, bending, and joining are combined with a deep understanding of design for manufacturability.

We are equipped with the latest and best in sheet metal fabrication technology, including AMADA laser cutting and punching combination machines and CNC bending machines that enable extremely precise and predictable forming of even the most sophisticated shapes. Contact us to discover how easy it is to get the benefits of high quality sheet metal fabrication services from an experienced and fully equipped sheet metal fabrication specialist.