Sheet metal fabrication skills and technology are often challenged by the special requirements of products that need to be both functional and stylish. Taiwa is a leader in matching style and function in sheet metal design to create beautiful products which match their intended purpose. Let’s have a look at the example of a drip coffee stand and other coffee serving accessories to see how to combine style and function in sheet metal fabrication.

How does combining function & style affect sheet metal fabrication?

In a contemporary high quality sheet metal fabrication workshop we have the technology to make almost anything, in any shape or size, by cutting, forming, bending, and joining different thicknesses of sheet metal materials. Functional objects have their own design challenges, including design for manufacturability, but with experience, skill and suitable technology these can be solved and even used as opportunities to improve the existing design.

When you add artistic and stylistic design elements to a sheet metal fabrication project you are adding a new form of complexity, which makes you combine engineering excellence with aesthetic look and feel. Often form and function can be integrated into a pleasing style by paying close attention to quality of materials and excellence in fabrication.

Perfection & excellence in sheet metal fabrication

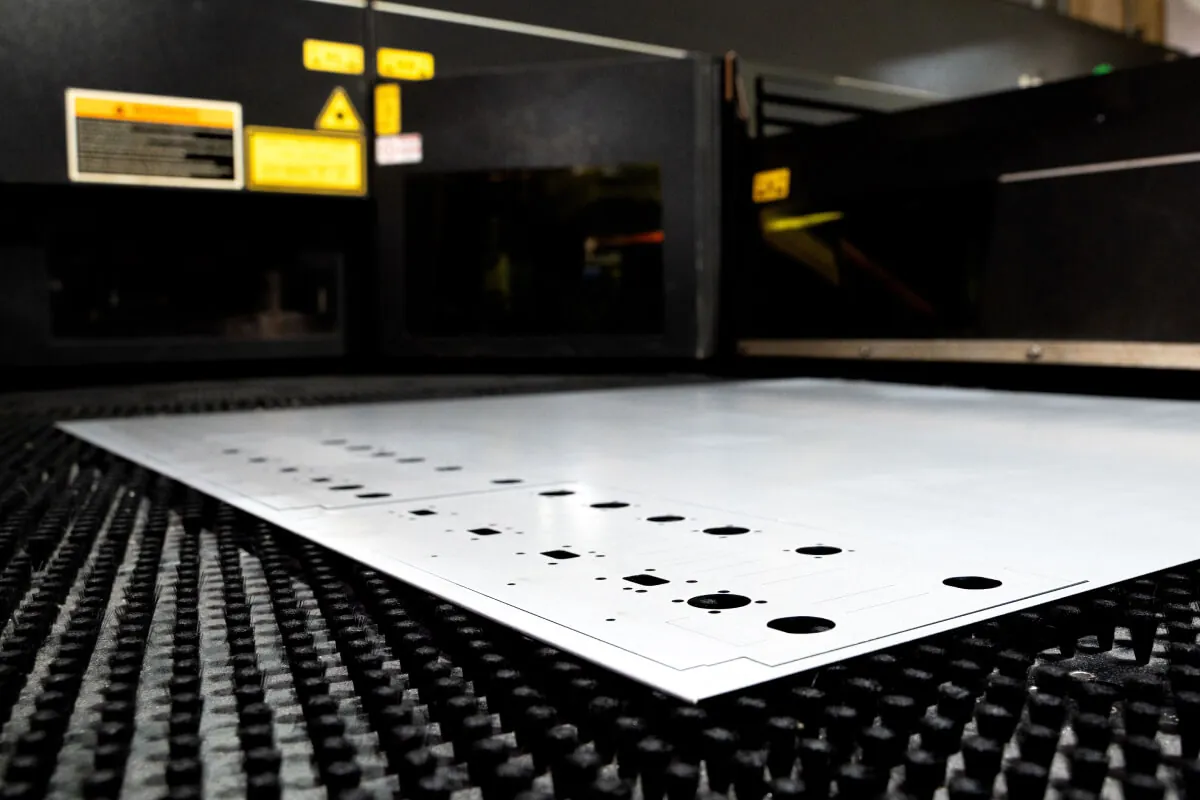

Any errors in alignment, joining or forming detract from the visual and physical appeal of the product, so perfect fabrication skills and excellent technology are essential starting points for stylish product manufacturing in sheet metal. At Taiwa we use virtual testing of bending and spring-back to ensure exact forming of metal sheets, and our AMADA laser cutting and punching combination machines deliver sub-millimetre accuracy with ease to ensure components are cut exactly to the correct size.

Maintaining excellent surface finishes relies on good material handling and assembly procedures, which can be overlooked in a busy industrial workshop. At Taiwa we keep our assembly team separate from the fabrication area to protect our workers, and minimize the risk of scratches or damage to components during and after assembly.

What do we need to know to achieve perfect sheet metal fabrication?

There are five important questions that we need to answer to optimize a high quality sheet metal fabrication design. Let’s see how we can apply those to our design work on the drip coffee stands that are shown in the pictures above.

1. How much daily use will the finished product have?

A stylish drip coffee stand is designed to be used every day, so it has to be durable and have a strong finish to keep it looking good. Products that are frequently used need more attention to details of how they can be cleaned and maintained, and any moving parts will need to be engineered to match reliability and durability requirements.

2. Is rust and corrosion resistance important?

Any food or beverage product has to be rust and corrosion resistant, and a drip coffee stand must be easy to keep clean and stain free as well. Most sheet metal products have basic corrosion resistant coatings, but products that will be exposed to wet or acidic environments need to be manufactured from corrosion resistant metals. These drip coffee accessories are made of 304 stainless steel for optimal strength and corrosion resistance.

3. Will it be on display?

This product is designed to work as a talking point in private, commercial or office use. It has an additional function as a way of showing excellence in design and sheet metal manufacturing, so it has to look good on display. Aluminum finishes can be brushed or anodized, stainless steel can be highly polished or brushed. Another alternative is epoxy or powder coating for a smooth and durable colored finish.

4. Does the product need to be heat resistant?

Without burners or heating elements, this sheet metal product needs to be able to resist the temperature of boiling water, 100C, which is easily achieved in sheet metal fabrication. It is important to ensure that other plastic or wood components will remain stable at this temperature, however.

5. What mechanical forces will it need to withstand?

Cantilevered designs need to be stronger than arches to withstand the same force, as they have only one side supported. When calculating the material thickness required, this is an important consideration to ensure that when the filter funnel is full of hot water the supporting stand does not sag or distort.

How does Taiwa create a stylish, functional sheet metal product?

At Taiwa we combine very high levels of engineering and design skills with the latest in sheet metal fabrication technology. This enables us to guarantee that we can manufacture the optimum design for your project. We also have extensive experience working with artists and designers to create unique and special products and art pieces, which has helped us expand our knowledge of form, style and finishes to match our technical and engineering skills. We make it easy to access professional sheet metal fabrication services that meet your needs.

- Functionality

- Aesthetic Appearance

- Durability

- Cost Efficiency

We work closely with our customers to ensure that all the requirements of their project are met through excellence in design, materials, fabrication and quality control. Sharing our experience of manufacturing a wide range of sheet metal products enables us to optimize designs and reduce manufacturing costs while retaining the highest standards of engineered performance and quality finishes. Contact us to discover how our expertise can help you combine style and function in your sheet metal fabrication project.