Rising interest in Coffee Culture in the domestic and commercial culinary industry has created increasing demand for high quality sheet metal roasting, brewing and serving products as part of growing interest in kitchen appliances and tools. The quality of folding and finishing on culinary equipment has to satisfy the exceptionally high standards of customers who are accustomed to culinary equipment that has both functional and aesthetic appeal.

Why is sheet metal fabrication of culinary equipment special?

Culinary products are aimed at a market segment that requires the sheet metal manufacturer to work to the highest standards of finish and cleanliness. There are also extra safety requirements beyond being easy to clean and being manufactured from food grade materials. Culinary machines and equipment may need to be safe around children or busy employees who have machines in constant use.

Contemporary domestic and commercial kitchen and cooking environments are a visible feature of modern living and work spaces. Because of this, there is significant pressure on manufacturers of culinary equipment to ensure that it is worthy of display in a modern home, restaurant, or cafe environment. Modern culinary equipment has become a common focal point for conversations and enhances the dining experience by adding aesthetic appeal.

The perfect bends, welds, and PVD finishing of the Taiwa Nonagon coffee roaster base, shown above, is a good example of the high quality construction and finishing that is required by contemporary customers for sheet metal culinary products.

What’s the difference between domestic & business kitchen tools?

Both domestic and business customers need easy-to-clean antimicrobial kitchen tools, at reasonable prices, that can evolve with the changing fashions in food and material manufacturing industries. Primary considerations for domestic and commercial consumers may differ, however, especially in relation to design ‘look’ and finish.

Domestic appliances may be used less often, but also have to take up less space, whereas commercial culinary machines are in constant use in dedicated environments that have high health and safety standards. Specialist domestic culinary appliances, like coffee roasters, are more likely to be used as a talking point for guests and be used to generate a lifestyle experience, whereas commercial machines may be more utilitarian in look and feel.

How do you manufacture sheet metal culinary products?

Thinking about the uses and needs of culinary products, it becomes clear why they need to be manufactured to reliable, repeatable, high standards using appropriate materials and finishes. These products require careful quality control, and this is why cutting, folding, joining and assembly of sheet metal kitchen equipment are best carried out as a continuous process by one sheet metal manufacturing partner to ensure consistent results.

You need a sheet metal fabrication partner who has a good track record in similar product design and manufacturing. This includes an understanding of the needs of customers and users of culinary products, as well as expertise in the materials and finishes required. High grade stainless steel with bright finishes or hard PVD coatings are the standard in this industry, and require careful attention and handling to ensure fault-free results.

Do you need to be an expert in sheet metal fabrication to design kitchen products?

It doesn’t matter if you are not a highly experienced sheet metal product designer if you have a great concept you want to bring to market and an expert partner who has the design and fabrication technology to turn your concept into reality. At Taiwa we turn our skills and experience to finding the best way to successfully fabricate your product.

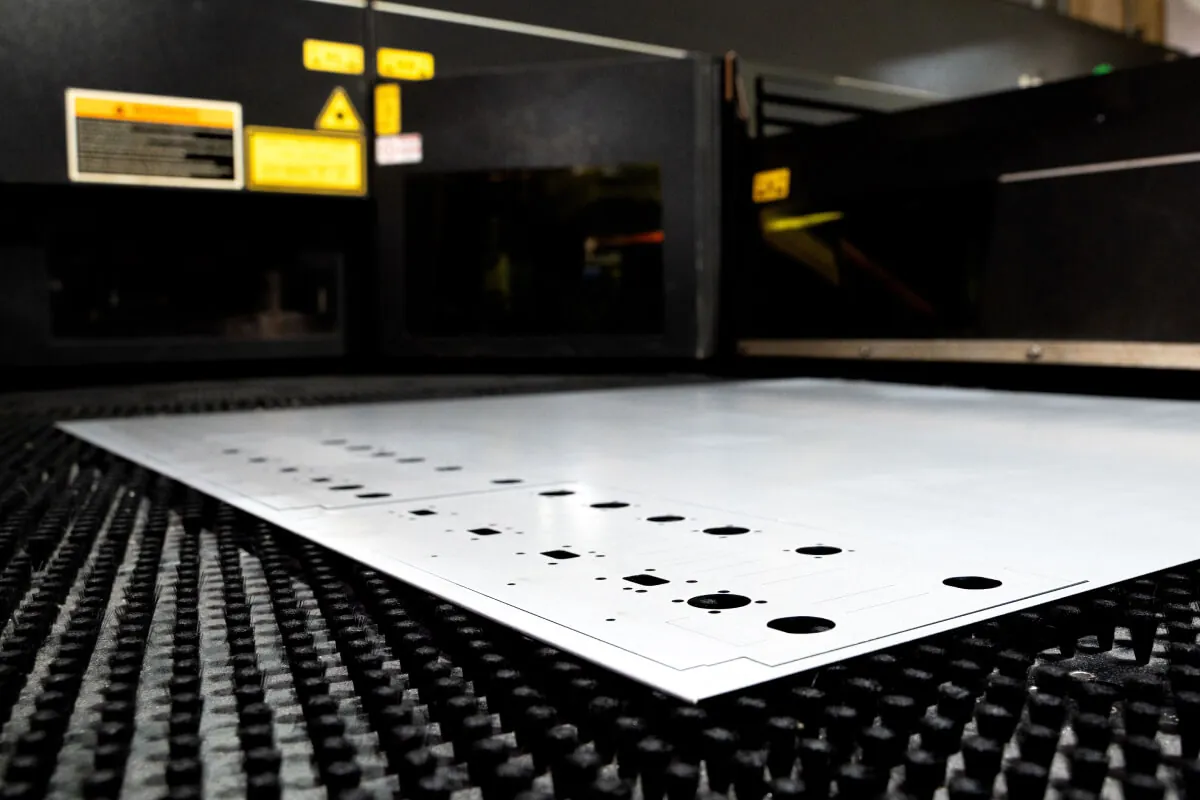

At Taiwa, we only use the best sheet metal fabrication technology, including AMADA laser cutting and punching combination machines and high precision CNC bending and forming machines for ultra-precise fabrication of complex shapes to the highest quality standards.

Our expertise in cutting, forming, bending, and joining are combined with in-depth experience in design for manufacturability that is a perfect combination for sophisticated, functional and aesthetically pleasing culinary sheet metal fabrication projects.Our experienced team can advise on modifications, innovations and adjustments to your design that can be integrated to improve finishes, functionality or cost-effective manufacturing.

The culinary industry loves accessories and our team also has a wealth of experience in accessory design that we can offer to assist in optimizing and developing your design portfolio to get the best results. Contact us to discuss your designs and find out how we can be your expert sheet metal fabrication partner for any culinary project.