Sheet metal parts fabrication includes many standard metal fabrication techniques including metal laser cutting, sheet metal bending and welding in ferrous and non-ferrous metals. Taiwan metal processing expertise is globally recognized, and includes Taiwan sheet metal fabricators and metal fabrication companies supplying the full range of stainless steel fabrication and sheet metal fabrication services.

What are the types of sheet metal parts fabrication?

Sheet metal fabrication is a term used to describe all types of precision sheet metal parts manufacturing that are commonly carried out in metal fabrication shops using a range of metal cutting, metal bending, welding and assembly technologies and techniques.

- Metal laser cutting

- Punch / laser cutting

- Sheet metal bending

- Sheet metal forming

- Gas Metal Arc Welding (GMAW)

- Flux Cored Arc Welding (FCAW)

- Gas Tungsten Arc Welding (GTAW)

- Finishing

- Surface treatment

- Automated component assembly

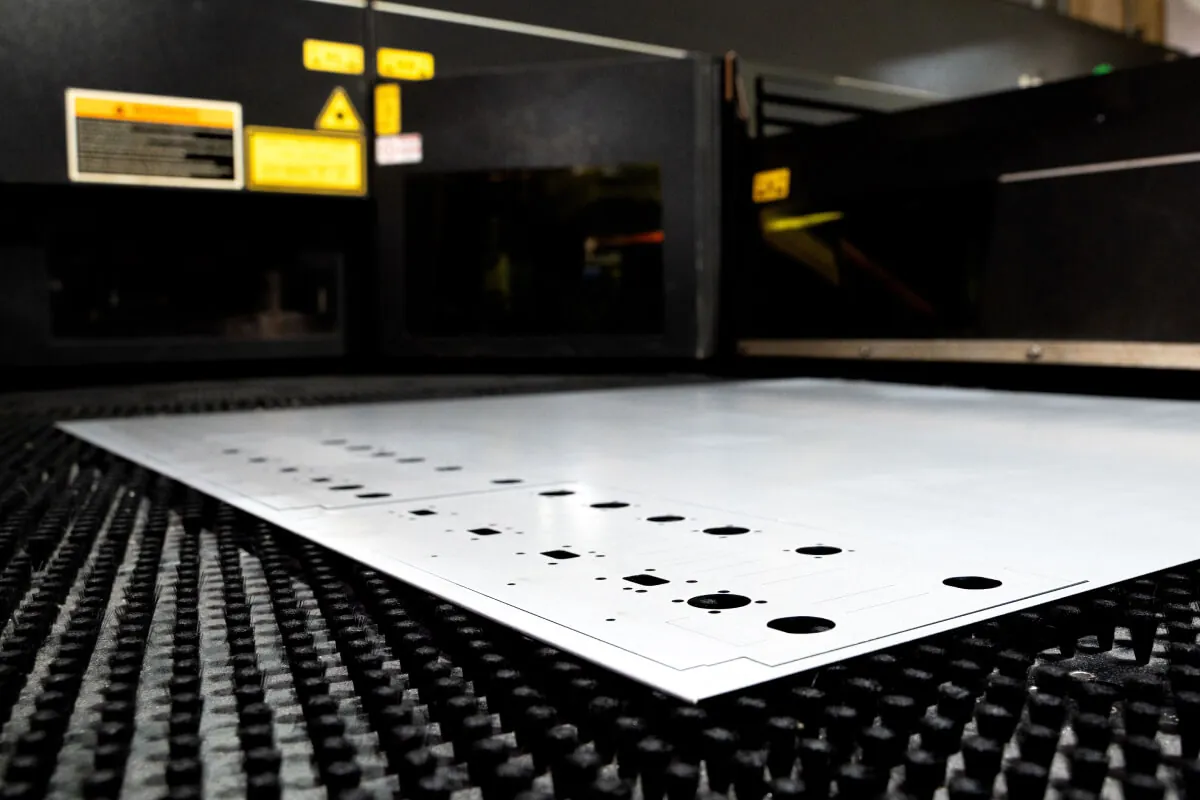

Metal laser cutting

Metal laser cutting enables the cutting of pipe, square sections, sheet and bar very precisely to match the exact requirements of the engineering design drawing. It is especially useful for cutting irregular shapes and cutting hollow sections without deformation or mechanical distortion. Exact control of heat transfer enables complete control over tempering effects on the characteristics of the sheet metal being cut.

Punch / laser cutting

Combination punch/laser cutting increases the speed of throughput and the accuracy of complex cutting tasks by achieving all cuts in a single pass without repositioning. The combination of precision punching and metal laser cutting services allows the sheet metal fabricator to select the optimum method for each cut or perforation being made in the metal sheet for optimal efficiency and accuracy. We use AMADA Fiber and CO2 laser cutting technology for the highest precision available today.

Sheet metal bending & forming

After the cutting of sheet metal stock, the next stage is usually to carry out forming and bending to create any three dimensional product like an electrical enclosure or equipment box. Accurate bending relies on a combination of excellent technology and operator skill. Specific tooling is used to create bend of different bend radius. This is very expensive to manufacture if your sheet metal fabrication service does not have the tooling in their existing library. Taiwa has

Welding technology

The three main types of welding technology used in sheet metal fabrication (GMAW, FCAW and GTAW) are used for different purposes depending on the type of metal sheet and the finish required. GTAW is best for very high accuracy and clean finishing, and FCAW is a simple solution for inexpensive fabrication of thicker metal sections for industrial projects or where visual appeal is less critical.

Finishing

Cutting, welding, and forming, especially of thicker materials, can create unevenness that needs to be smoothed out by grinding, sanding and polishing. This includes removing heat and flux marking caused by welding and the smoothing of sharp edges where they may be exposed and cause a risk of injury.

Surface treatment

Powder coating, PVD, galvanizing, electroplating and screen printing are all methods of surface treatment. Some sheet metals have a highly polished finish which may need brushing to reduce reflection, or a customer may want a bright polished finish. We can provide many different types of surface treatment in different colors to suit any preference for improved durability as well as visual appeal.

Component assembly

Component assembly is often overlooked, but is an essential service that should be available from sheet metal fabricators. Vertically integrated sheet metal fabrication services, from design through to assembly, ensure maximum quality control and enable rapid identification and correction of design for manufacturing issues that can cause costly delays and problems for customers.

How important is the latest technology in sheet metal fabrication?

Laser cutting services for metal laser cutting have revolutionized the first stages of precision sheet metal fabrication by increasing accuracy and reducing waste. Combination punch laser cutting machines like the AMADA laser cutting and punching combination machines we use at Taiwa enable extreme precision and exact repeatability without distortion.

Our capabilities in metal forming and metal bending have been transformed by advanced AMADA CAD/CAM design software. This enables us to accurately model every bend digitally in advance, including deformation and spring-back characteristics, significantly reducing prototyping time and cost overheads.

In the Taiwan metal processing industry, Japanese AMADA press brakes are the leading technology for metal bending and the full range of AMADA machines enable precision sheet metal fabrication with a speed, accuracy, and reliability that is far superior to what could be achieved by the previous generation of metal fabricators.

At Taiwa we have deliberately followed a continuous improvement and upgrading pathway to ensure we meet the highest international quality standards through technology upgrades and both in-house and external training and professional development for our metal fabrication team.

Working with steel & stainless steel can be challenging

Steel and stainless steel fabricators need to be able to meet the challenges of working with a wide range of different steel alloys including SPCC, SS400 rolled steels and both 304/304L and 316/316L stainless steel. Techniques and tooling for sheet metal bending, metal laser cutting and precision sheet metal fabrication vary for different grades of steel, and it is important to ensure that you select an experienced sheet metal fabrication company with a fully equipped fabrication shop as your metal fabrication partner.

Choose Taiwa for sheet metal parts fabrication

Our integrated design, manufacturing, assembly and shipping services means we can always find the best solution to manufacture your sheet metal product. As a one-stop-shop we combine our design experience, state of the art manufacturing technology, and expert finishing and assembly skills to deliver the best possible results every time.

- Highly trained & expert designers & machine operators

- Expert customer service & engineering support teams

- 300 hours of employee training & examination to become a Taiwa machine operator

- Taiwan TTQS Workforce Quality Certification

- ISO 9001 & ISO 14001 certified

- Extensive library of bending dies & tooling

- Frequently calibrated Japanese AMADA cutting, punching & forming machines

- Experts in material technology

- Complex assembly capabilities with multiple processes and components

Taiwa puts more than 20 years of experience in precision sheet metal fabrication to work on your project. Over this time our production capacity has evolved to enable us to manufacture almost any requirement, from desk calendars to bus shelters.

- Up to 3000 mm sheet length

- 0.3 mm to 20 mm sheet thickness

- Flatness maintained to 0.2 mm

- Verticality within 0.15 mm

- Functional, practical design assistance

- Manufacturing for aesthetic appeal

- Design for manufacturability

- High quality assembly and finishing

We maintain an extensive library of tooling and forming jigs to enable rapid setup for almost every possible metal folding design and our efficient modern manufacturing processes reduce energy consumption and waste for greener manufacturing. Contact us to find out how our sheet metal fabrication services can easily help you create perfection for your sheet metal parts fabrication project.